Worki

Co mamy przenosić ?

Aktualności

Uczestniczymy w różnego rodzaju wydarzeniach oraz targach branżowych. Dzięki takim imprezom jesteśmy w stanie w krótkim czasie przedstawić…

Dystrybutor urządzeń transportu bliskiego - Id-lifting

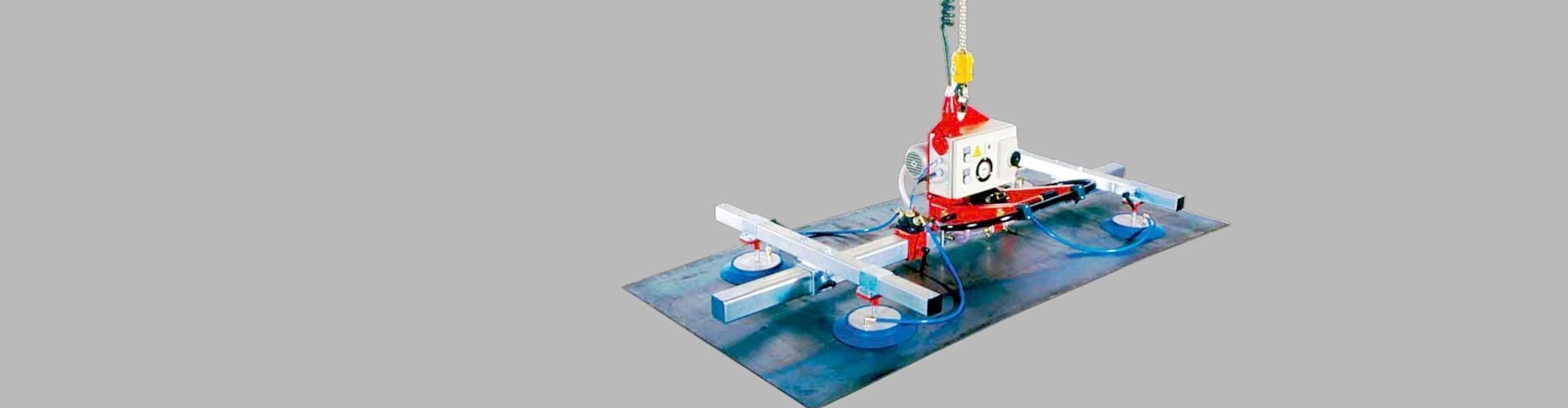

Od 2011 roku firma Id-lifting zajmuje się dystrybucją urządzeń do transportu bliskiego. Z naszej oferty skorzystało tysiące przedsiębiorstw przemysłowych oczekujących nie tylko sprzętu doskonałej klasy, ale przede wszystkim kompleksowego doradztwa technicznego. Z chęcią pomożemy Państwu wybrać sprzęt, który będzie w 100% dopasowany do rodzaju działalności, tempa pracy i konstrukcji waszej hali przemysłowej. Dzięki współpracy z czołowymi producentami maszyn, jesteśmy w stanie znaleźć rozwiązania dostosowane zarówno do branży, w której działacie, jak i oczekiwań, jakie nam przedstawicie.

Przenoszenie produktów, części lub innych elementów, na przykład w procesie produkcyjnym czy podczas magazynowania, wymaga nie tylko sprawnego sprzętu. Urządzenia służące do wykonywania powyższych czynności powinny pracować wydajnie, zapewniając wysoką funkcjonalność podczas realizowania każdego zadania. Dlatego w naszym asortymencie znaleźć można tylko sprawdzone modele urządzeń transportu bliskiego. Oferujemy maszyny ergonomiczne i bezpieczne, które będą nieocenionym wsparciem w wielu procesach technologicznych.

Wsparcie techniczne dla wszystkich klientów

Klientów, którzy nawiązują z nami współpracę i decydują się na zakup naszych maszyn, nigdy nie zostawiamy bez technicznego wsparcia! Doświadczeni doradcy z naszej firmy organizują dla Państwa profesjonalne testy sprzętu, pokazy techniczne oraz konsultacje. W razie konieczności zapewniamy również serwis urządzeń transportu bliskiego.

Produkty

Nasz asortyment tworzą urządzenia transportu bliskiego o sprawdzonych parametrach, doskonale sprawdzające się w wielu branżach. Jeśli szukają Państwo rozwiązań technicznych ułatwiających transportowanie ładunków o różnej wadze, które pozwolą na wydajniejsze realizowanie procesów w firmie, zachęcamy do bliższego zapoznania się z ofertą produktową.

It's all possible

Nasi Klienci